how to understandWhat is the development status of electrolytic capacitors ? In terms of production value,Aluminum electrolytic capacitorsThis type of capacitor was originally an ordinary DC capacitor, but now it has developed from DC to AC, from low temperature to high temperature, from low voltage to high voltage, from general type to special type, from general structure to chip, flat, Book-like structure.

Its upper limit capacity has been extended to about 4F, the operating frequency has reached 30kHz, the operating temperature range has reached -55℃-125℃, and some are even as high as 150℃, and the rated voltage has reached 700V. In short, the development of aluminum electrolytic capacitors is becoming more and more widespread. The basis for these developments is as follows:

1. In terms of materials

The aluminum foil used now is very particular in composition and structure. High purity is no longer required. For example, for anode foil, the purity is required to be high enough. In order to improve the number of initial corrosion points, mechanical strength and performance of the dielectric oxide film, certain impurities must be appropriately contained in the foil. And some use alloy foil. In terms of structure, for low-voltage foils, the cubic structure is not required to account for a large proportion, but for high-voltage foils, this structure is required to account for more than 80% to 90%. To the cathode foil. In order to increase its specific volume, alloy aluminum foil with a certain impurity content and irregular grain orientation is required.

The working electrolyte consists of three components. That is, solvents, solutes and additives. For example, the electrolyte that has been used for a long time is composed of ethylene glycol, glycerin, boric acid and ammonia. Due to the development of aluminum electrolytic capacitors, this electrolyte is far from meeting the requirements, so many new electrolytes have been produced to reduce the working temperature range of the capacitor (such as -55℃-125℃). The formula principles of these new electrolytes are:

① Mix two solvents. to achieve complementarity.

② Use two weak acids to provide the two required anionic groups.

③Add alkali, such as organic amine, to adjust the pH value and flash voltage of the electrolyte. Change its resistivity.

④Additives that improve the properties of the electrolyte, such as phosphoric acid or its salts that prevent hydration of the aluminum oxide film, dinitrobenzene that absorbs hydrogen, and ethylene oxide that increases the flash voltage of the electrolyte.

2. In terms of technology

In addition to the completion of production mechanization and automation, the technological progress of aluminum electrolytic capacitors is mainly in two processes: corrosion and empowerment. The corrosion coefficient of aluminum foil is not only very high (low-voltage capacitor foil has reached 100, and high-voltage capacitor foil has reached 25), but it can also corrode aluminum foil with different pit shapes according to the performance requirements of the capacitor.

The etching process is a dynamic balancing process of etching liquid type, concentration, temperature, original foil composition, structure, surface condition, foil speed during etching process, and power supply type, waveform, frequency, voltage, etc. The problem is how to get a good dynamic balance and how to confirm a good balance according to the requirements. Therefore, it cannot be said that the corrosion process has reached a lot of status.

The current enabling process can now produce high-quality dielectric oxide films, and can also produce different dielectric oxide films according to different requirements. For example, for DC capacitors, γ and γ'-type crystalline aluminum oxide films can be manufactured. AC capacitors are amorphous films. The biggest progress in the empowerment process is that it can convert the aluminum hydroxide film into a dielectric aluminum oxide film and form a waterproof layer on its surface. In addition, defects and cracks in the dielectric film can be eliminated.

3. In terms of structure

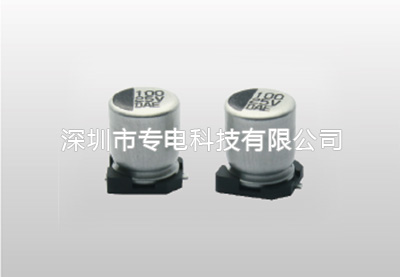

The structure of aluminum electrolytic capacitors is now diversified, in addition to the above-mentioned liquid aluminum electrolytic capacitors. There are also solid aluminum electrolytic capacitors. There are two main structural methods, one is a foil-type winding type, and the other is an aluminum powder sintered porous block. The solid electrolyte used is mainly MnO2.Chip capacitor

The structures of aluminum electrolytic capacitors are now diversified, such as double anode structure, counter-cathode structure, book structure, triangular structure, and chip structure. Among them, the emergence of chip aluminum electrolytic capacitors is another advancement of aluminum electrolytic capacitors. Because without high specific volume aluminum foil, high-temperature resistant electrolyte, excellent sealing structure and fine processing technology, it is difficult to produce chip aluminum electrolytic capacitors that meet the requirements, and the chip production rate is still relatively low. level.Automotive capacitor