Chip resistance heating refers to a method of electrically heating materials using the thermal effect of current flowing through a resistor. Chip resistance heating is used in everything from heating molten metal to heating food. Using electric heating, it can heat metals, molten metals and non-metals, the efficiency can reach 100%, and the working temperature can reach 2000℃. It is used for high-temperature heating and low-temperature heating. Due to its controllability and rapid heating properties, chip resistance heating is used to heat everything from molten metal to food.

Chip resistance heating uses heat energy generated by the Joule effect of current passing through a conductor to electrically heat objects. Chip resistance heating can be divided into direct chip resistance heating, which allows the current to pass through the conductive medium of the electric heating element, such as chip resistance wire, thermal chip resistor (PTC), electric heating film, etc., so that the electric heating element generates heat. The heat generated by the electric heating element directly heats the object through thermal conduction, thermal convection and thermal radiation. The traditional method of embedding electric heating elements into the mold to heat the mold is to directly heat the chip resistor.

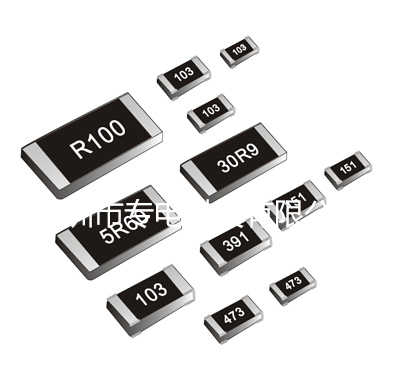

The operating principle and characteristics of thermal chip resistors

Generally speaking, the relationship between metal thermistor chip resistance and temperature can be expressed by the following approximate formula, namely RT=RT0[1]+α (usually above several thousand ohms). The interchangeability is poor, the nonlinearity is serious, and the temperature measurement range is only - about 50~300℃. It is widely used in temperature detection and control of household appliances and automobiles. Metal thermistor chip resistors are generally suitable for temperature measurement in the range of 200 to 500°C. Its thermistor measurement is accurate, stable and reliable. It is commonly used in process control.

Thermal patch resistance material, thermal patch resistance temperature measurement is based on the characteristic that the patch resistance value of the metal conductor increases with the increase of temperature to measure temperature. Most thermal chip resistors are mostly made of pure metal materials. Platinum and copper are mostly used now. In addition, materials such as nickel, manganese and rhodium have been used to make thermal chip resistors.

The most commonly used temperature detection in medium and low temperature areas is thermal chip resistors . Let’s understand some of the working principles of chip resistors. The main characteristics of thermal chip resistors are high measurement accuracy and stable performance. Different from the thermocouple temperature measurement principle, the temperature measurement of the thermal chip resistor is based on the thermal effect of the chip resistor, that is, the resistance value of the chip resistor changes with the change of temperature. , the temperature can be measured by measuring the change in resistance of the thermal patch.