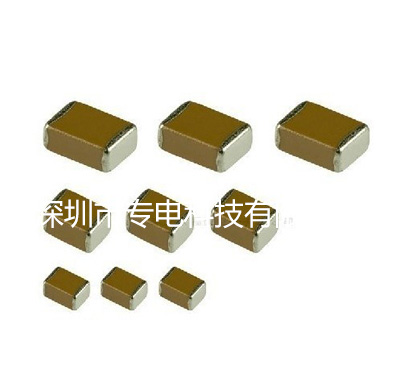

He Shentang HEC high voltage chip capacitor

Product introduction: Heshentang is the agent of He Shen Tang HEC high-voltage chip capacitors and conventional ceramic chip capacitors. A full range of products are in stock and ready for sale.

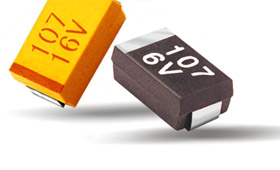

High-voltage chip capacitors, also known as ceramic multilayer chip capacitors, are made using ceramic powder production technology with precious metal palladium inside. Silver is plated on the ceramic as an electrode using a high-temperature sintering method. The product is divided into two materials: high-frequency porcelain NPO (COG) and low-frequency porcelain X7R. NPO has a small package size, a high temperature coefficient capacitor, and good high-frequency performance. It is used in highly stable oscillation circuits as circuit filter capacitors. X7R ceramic capacitors are limited to bypass or DC blocking in circuits operating at normal frequencies.

Consumer electronics, lighting applications, automotive electronics, home appliances, security monitoring, power energy, etc.

Small size and light weight;

Adaptable to reflow soldering and wave soldering;

The laminated electrode structure has stable electrical properties and high reliability;

Low assembly cost and matched with automatic mounting equipment;

High mechanical strength and excellent high frequency characteristics.

1. The working voltage of the capacitor must be lower than the rated voltage and must not be used exceeding the rated voltage.

2. The capacitor accuracy and material type should be selected reasonably.

3. Chip multilayer ceramic capacitors are all packaged in rolls. The model number is on the tape reel, but there is no mark on the capacitor. Although its capacity can be known by measurement, it is difficult to distinguish the accuracy level of the material category, so care must be taken during use, especially when assembling by hand.

4. Open chip trimmer capacitors cannot be wave soldered, while closed chip trimmer capacitors can be wave soldered.

5. Chip capacitors. Chip capacitors generally adopt a multi-layer structure. Some people use soldering irons to weld by hand when using them. At this time, you must pay attention to the welding speed to avoid overheating, which may cause the base terminals to break due to large temperature differences and reduce the capacity. .

6. Chip capacitors use ceramic substrates, which are thin and brittle. Some circuit boards are thin and will deform due to uneven force during installation, which can easily cause the capacitor to break. Multi-layer structures are generally used. Some people use soldering irons for manual welding. At this time, attention must be paid to the welding speed to avoid overheating, which may cause the base end to break due to large temperature differences and reduce the capacity.

7. Chip capacitors use ceramic substrates, which are thin and brittle. Some circuit boards are thin and will deform due to uneven force during installation, which can easily cause the capacitor to break.

Company advantages

01

YEARS OF ENTERPRISE ACCUMULATION, ONLY MAKING HIGH-QUALITY ELECTRONIC COMPONENTS

Many years of experience in sales agency for foreign brands, with a complete sales service system, first-hand supply, and first-class quality guaranteed

Covering YAGEO, SAMSUNG, HEC and other international brands, formal channels for overseas ordering and customs clearance, product sources are guaranteed

Sufficient supply to meet the supply and demand of massive electronic components in different industries

02

ELITE TEAM, DIAMOND QUALITY, ESCORTING YOU IN REAL TIME

Zhuandian Technology has reached long-term and in-depth cooperative relationships with a number of logistics companies, which can ensure the timely and safe arrival of logistics within the specified time.

Machine installation, returns and exchanges, freight and samples are included

03

IMPROVE THE SERVICE SYSTEM AND LISTEN CAREFULLY TO CUSTOMERS’ VOICES

7*24 hours dedicated online customer service to solve any of your questions at any time and provide you with the most considerate and comprehensive support

Provide timely inquiry and quotation services, and efficiently and quickly cooperate with customer procurement work

Comprehensive support from experts. If there are problems that are difficult to solve during the application process, you can apply for expert on-site support